In the competitive manufacturing landscape of the United Arab Emirates, keeping CNC equipment current with modern technology is essential for maintaining productivity and quality. Shan Salman, founder of Zavod Tech, specializes in helping UAE manufacturers achieve exactly that through expert CNC retrofits. His recent waterjet modernization project showcases how the right partnership between a skilled retrofit company and advanced control technology can transform aging equipment into a high-performance production asset.

The Client Challenge: A Waterjet System in Need of Modernization

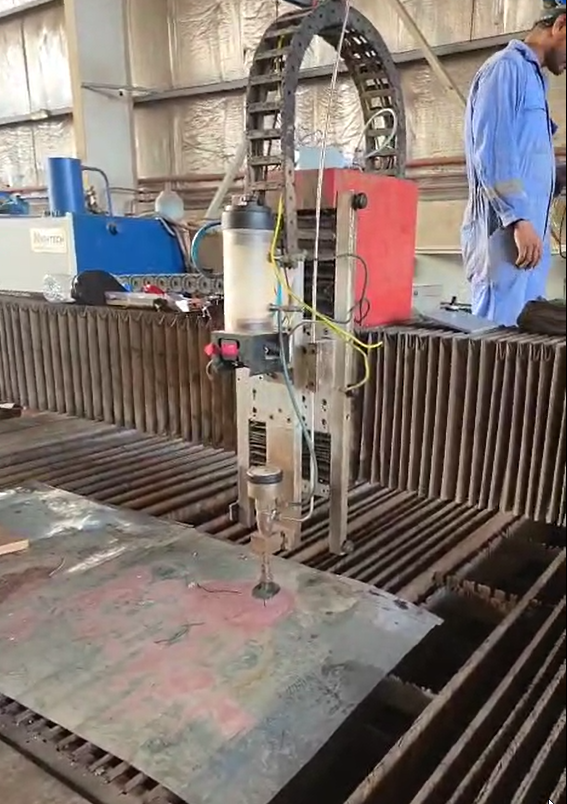

When a UAE-based manufacturer approached Zavod Tech, their waterjet cutting system was showing its age. While the mechanical components remained sound, the outdated control system was limiting productivity and making the machine increasingly difficult to operate and maintain. In Shan’s words, it was half dead.

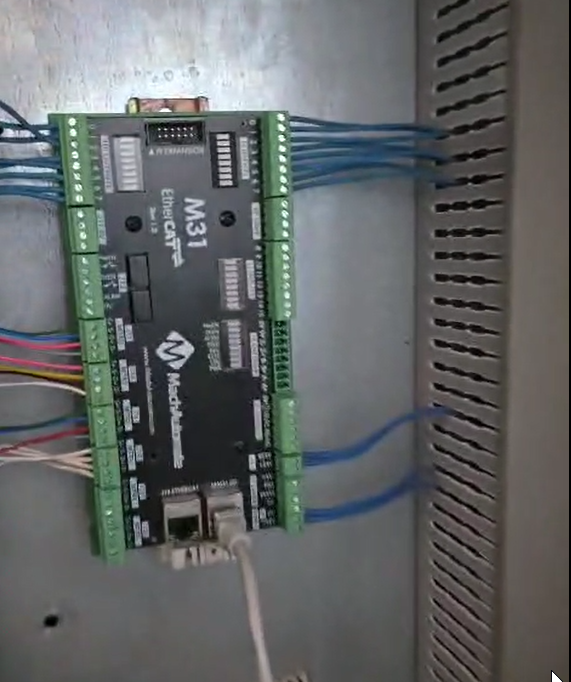

Rather than investing in a completely new waterjet—a cost that could easily exceed hundreds of thousands of dollars—the client turned to Zavod Tech’s expertise in CNC retrofitting. Shan’s solution centered on MachLabs’ M31 motion controller paired with MachPro CNC control software.

The Retrofit Solution: MachPro with the M31

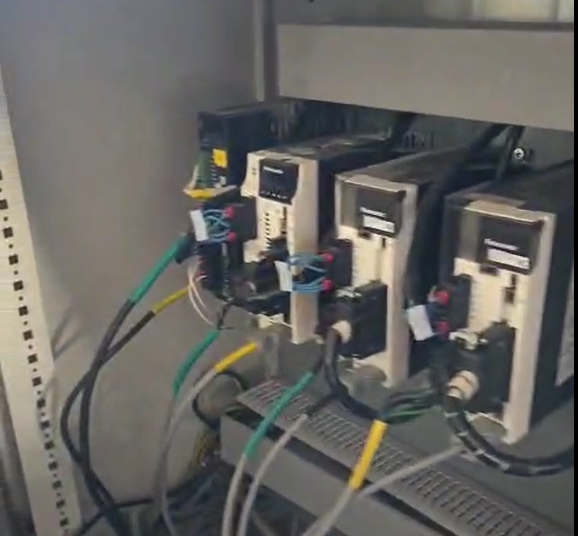

For this waterjet upgrade, Zavod Tech chose to use MachPro Waterjet CNC control software with the M31 motion controller. Shan wired his standard step and direction Panasonic servo drives directly to the M31. He has found Panasonic servos to be very reliable.

The M31 had enough inputs and outputs to control the waterjet.

The Right Tools Needed for This Project

As a professional retrofitter serving diverse clients across the UAE, Shan found some of the tools MachPro provided extremely helpful in the retrofitting process.

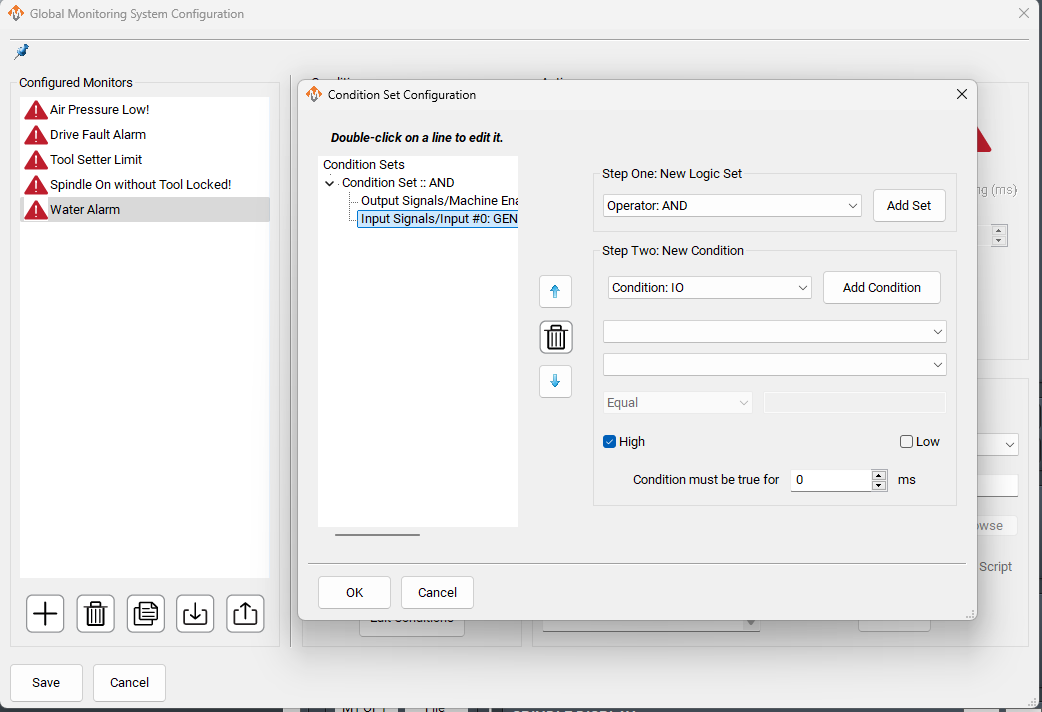

Global Monitoring System

Shan needed one of the inputs on the M31 to activate an alarm on his CNC control. By using the Global Monitoring System, he was able to simply configure the input to trigger the specific alarm he needed.

“I love this. It’s awesome. Works like a charm.” Shan Salman

Customizable Interface

Every shop has unique workflows and preferences. Shan was able to configure the screen just the way they needed by adding the buttons right under the DROs with the 5 Click Customization feature.

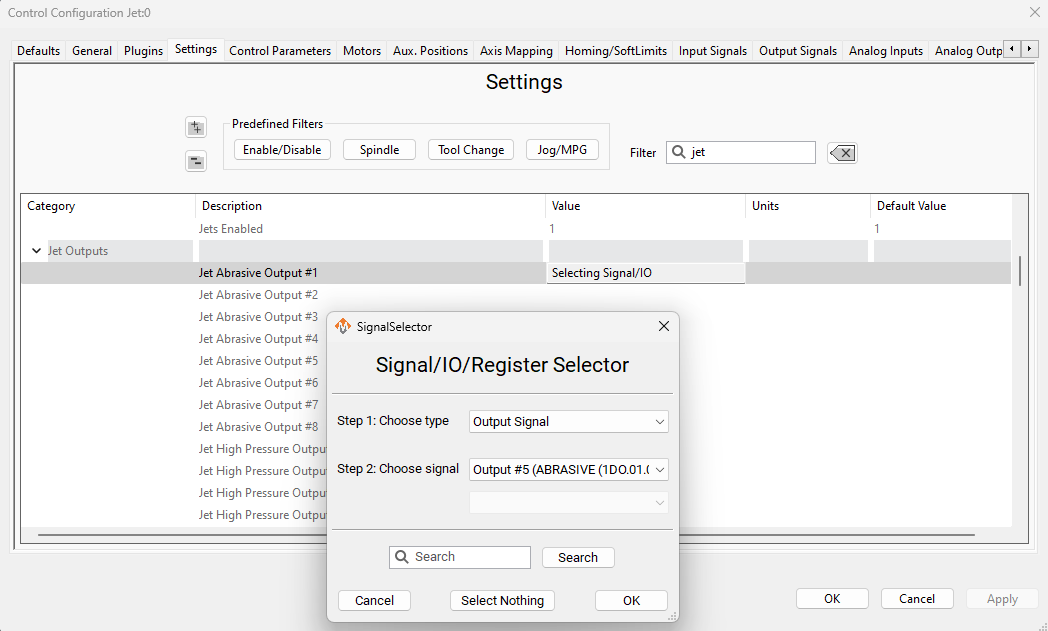

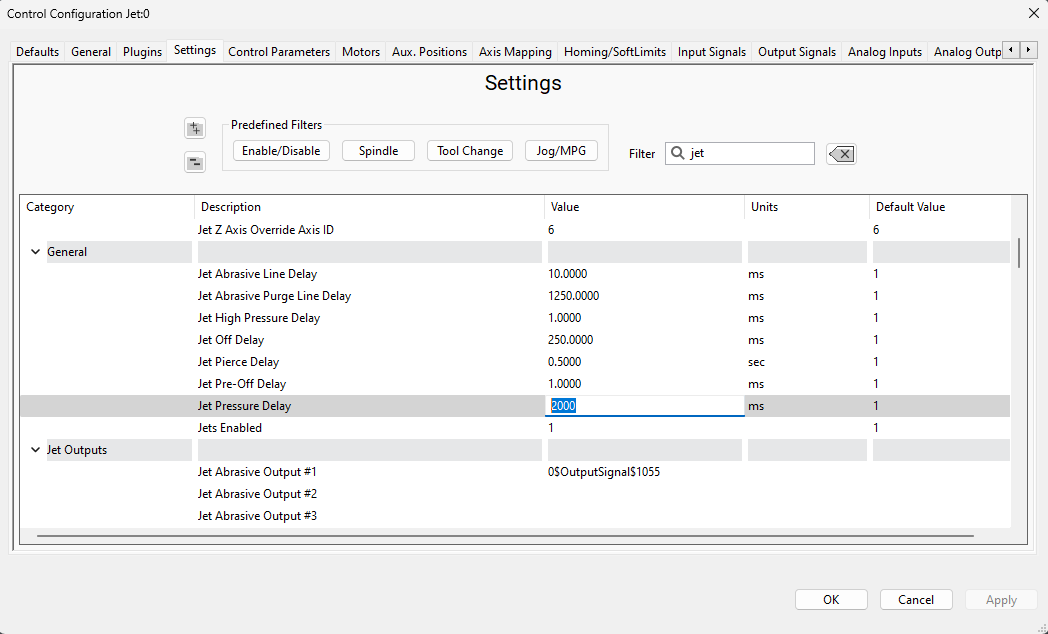

No Code Setup

For Shan, it simplified things not to have to write custom lua macros to get the waterjet running. Although he does program in lua and is able to create complex custom macros, for a standard waterjet everything was built in. He was able to configure his Pressure, Abrasive, and Pump outputs just be selecting the outputs.

Then he was able to adjust the delay between the Jet Pressure output and the Abrasive output in the settings dialog.

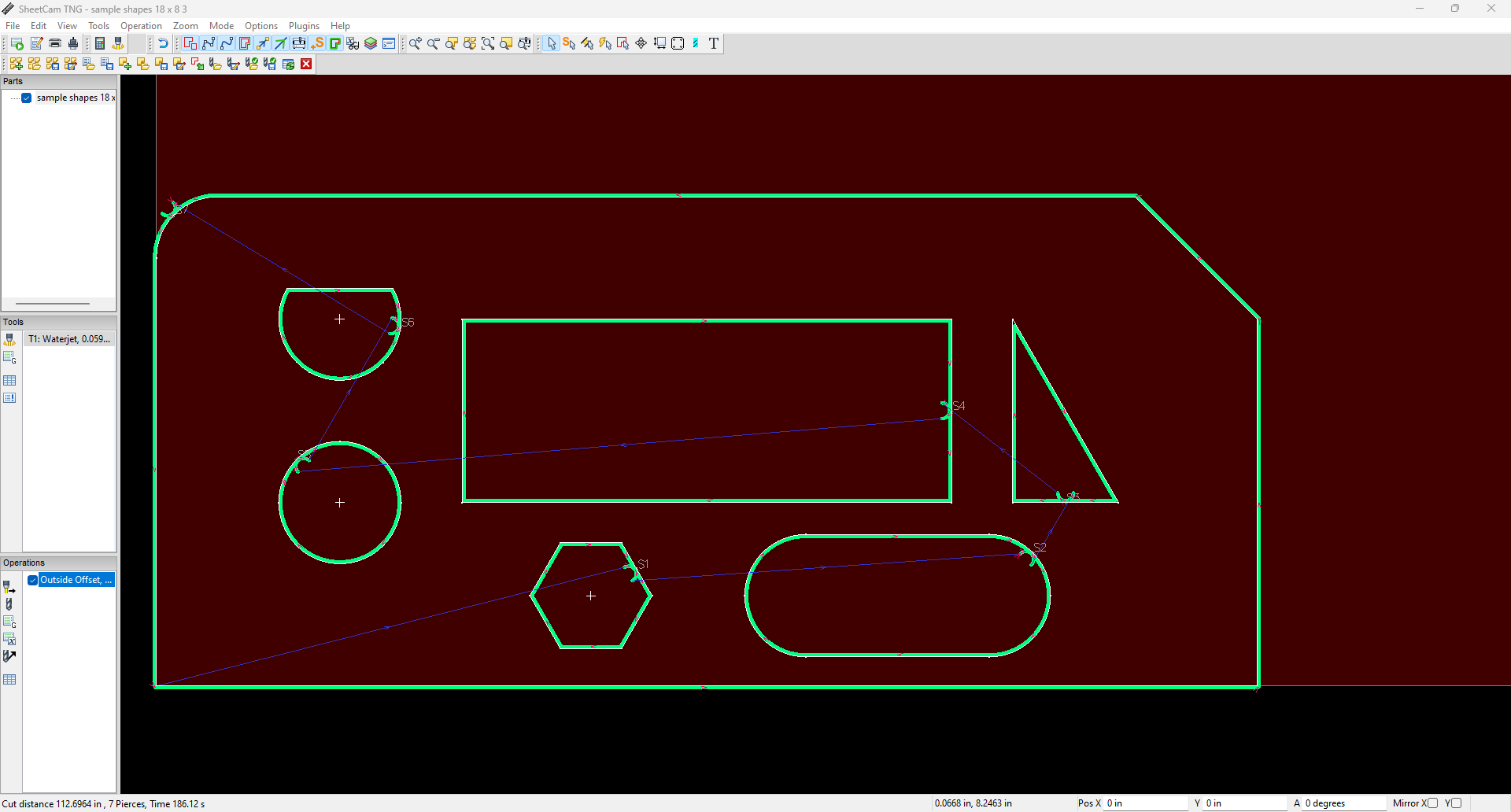

SheetCAM Integration

For nesting and toolpath generation, Shan selected SheetCAM—a cost-effective, user-friendly CAD/CAM solution that was perfect for his client’s waterjet operations. The software’s straightforward interface meant minimal training time while delivering professional nesting capabilities.

MachLabs provided a dedicated post processor specifically designed for MachPro, ensuring that SheetCAM generated precisely formatted G-code optimized for the waterjet system. This seamless integration eliminated post-processing headaches and allowed the client to move from design to cutting with confidence.

Real-Time Z-Axis Control

One feature that was a requirement for Zavod Tech’s client was the ability to jog the Z-axis while a G-code program runs. For waterjet cutting, where material thickness variations can occur across large sheets, this capability allows operators to make height adjustments on the fly without stopping production—preventing scrap and maintaining throughput.

MachPro Waterjet allows a user to configure that on a machine and Shan was able to have buttons added to the screen to jog the Z up and down.

The Results: A Transformed Production Asset

The completed retrofit delivered transformative results for Zavod Tech’s client.

The waterjet system now operates with:

- Modern control technology matching

- No more random faults constantly stopping production

- An intuitive operator interface reducing training requirements

- Accessible replacement parts and local EAU support for MachPro, M31, and the new Panasonic servo drives

- Extended equipment lifespan protecting the client’s capital investment

The client achieved all of this at a fraction of the cost of purchasing a new waterjet system, while maintaining the proven mechanical platform they trusted.

Serving the UAE Manufacturing Sector

Zavod Tech’s success with this project reflects the growing sophistication of the UAE’s manufacturing sector and the value of partnering with specialized retrofit experts. Companies across the Emirates are discovering that strategic modernization, executed by skilled professionals like Zavod Tech, delivers superior ROI compared to wholesale equipment replacement.

With the successful deployment of MachPro and the M31 motion controller, Zavod Tech has gained a powerful new tool for serving their UAE clients. Reflecting on the completed waterjet retrofit and watching the machine run in production, Shan shared his enthusiasm:

“This really opens my way to more retrofits to come.”

Looking ahead, Shan is already planning his next innovation. For upcoming projects, he’s eager to implement EtherCAT communication with the M31 controller. The prospect of simplified wiring and full encoder feedback has him excited about the enhanced capabilities this will bring to his clients. He’s even considering absolute encoders for the next retrofit—eliminating the daily homing routine and getting machines into production faster each morning.

By combining local expertise with world-class control technology from providers like MachLabs, UAE manufacturers can compete globally while managing capital expenses intelligently.

Connect With the Experts

Need CNC retrofit services in the UAE? Contact Zavod Tech to discuss how they can modernize your equipment.

Exploring control solutions for your retrofit project? Visit MachLabs to learn more about the M31 controller and MachPro software that made this transformation possible.

Are you a manufacturer in the UAE considering a retrofit? The solution might be closer than you think.Retry